产品中心

PRODUCT CENTER

新闻焦点

NEWS FOCUS

-

28

2025-09

伟德体育官方网站智中突破海量调频数据处理技术瓶颈,储能系统...

近日,伟德体育官方网站智中“海量调频数据协同处理技术”取得新进展。该项目针对大规模储能系统中高频、高并发数据处理的关键难题,突破多项技术瓶...

-

28

2025-09

伟德体育官方网站股份亮相第38届国际电力工业展览会

9月16-18日,欧洲能源界的目光齐聚波兰比尔斯科-比亚瓦——第38届国际电力工业展览会(Energetab)在当地会展中心盛大启幕。该展会是中...

-

28

2025-09

伟德体育官方网站股份闪耀亮相2025年亚洲国际电力能源展览会

近日,2025年亚洲国际能源电力展在泰国曼谷盛大启幕。作为东盟地区最具影响力的电力能源行业盛会,此次展会汇聚了全球顶尖设备制造商与...

-

28

2025-09

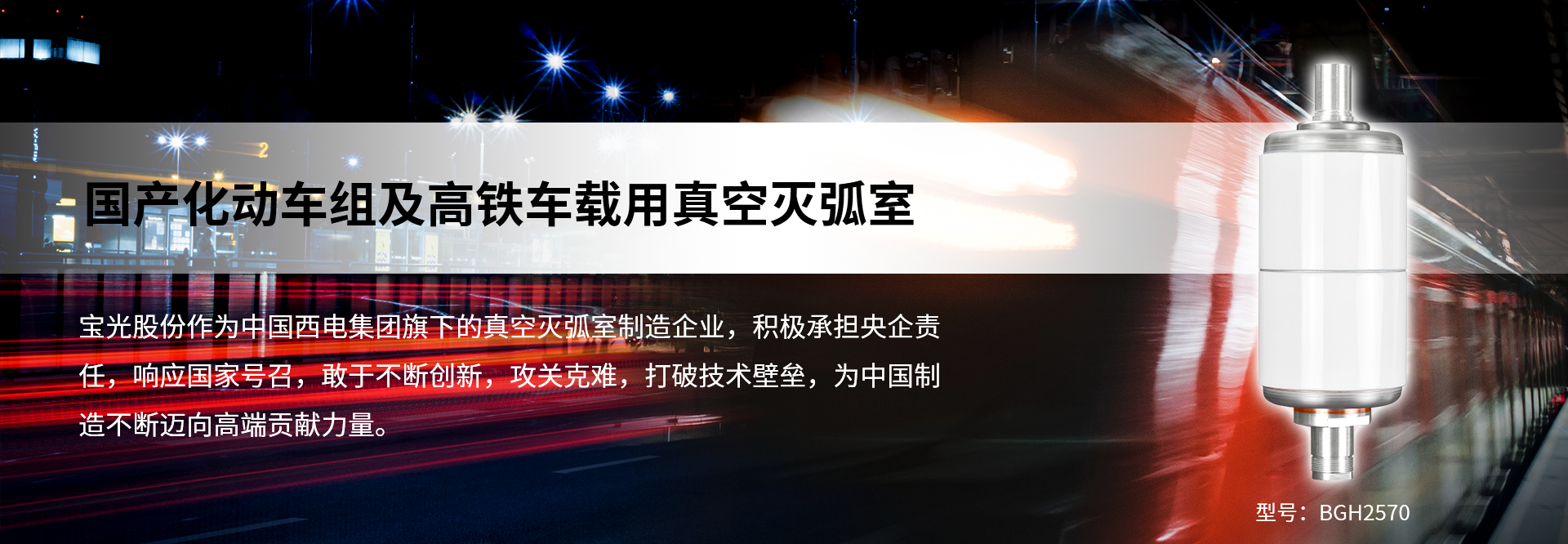

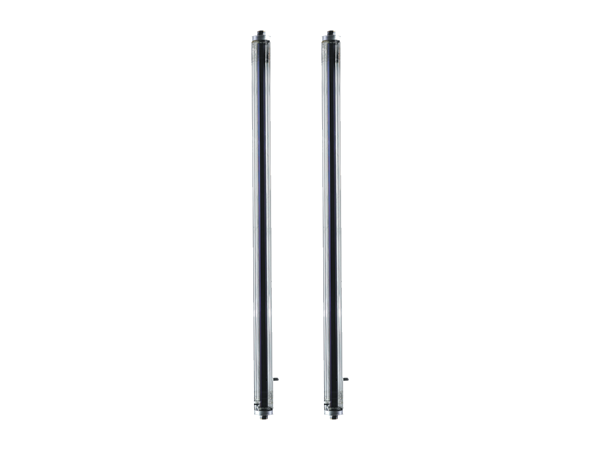

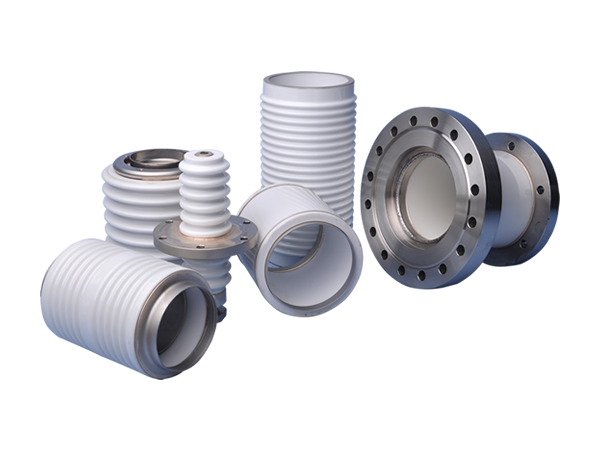

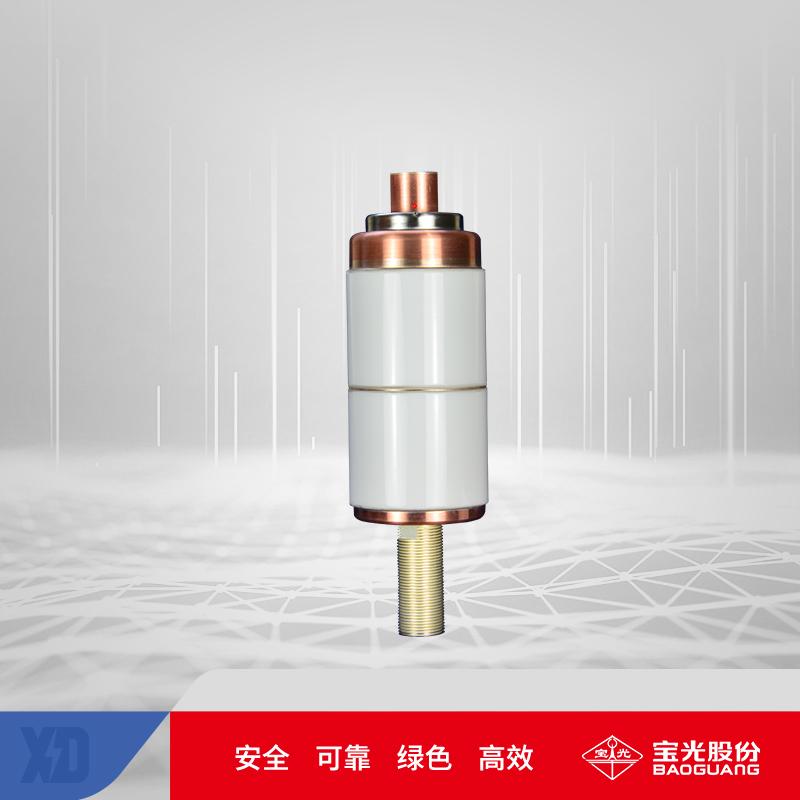

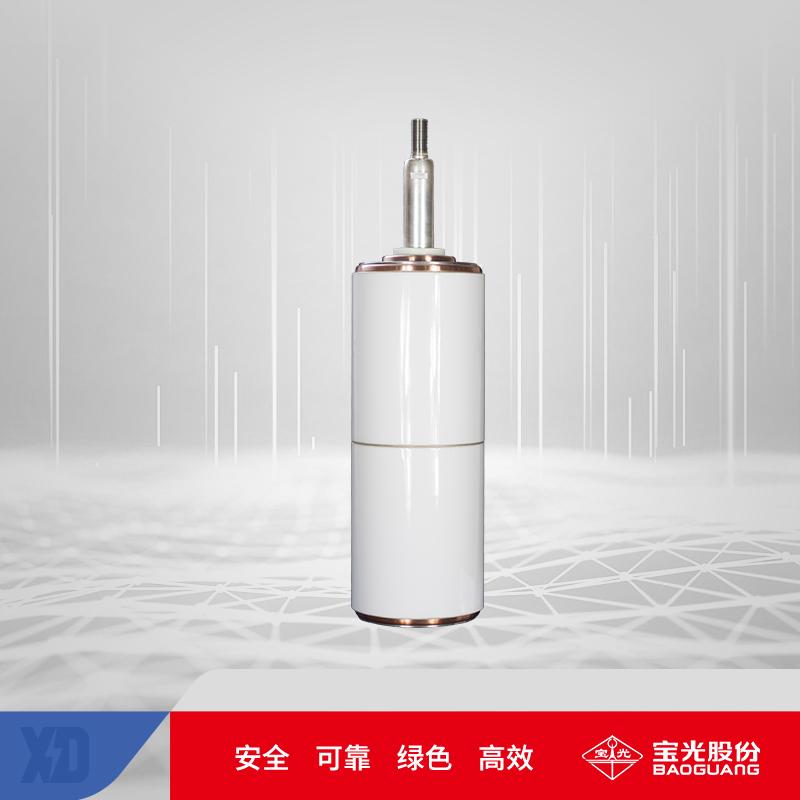

伟德体育官方网站股份参加第31届国际真空放电及电气绝缘会议

9月21-26日,第31届国际真空放电及电气绝缘会议(31st ISDEIV 2025)在成都天府国际会议中心召开,伟德体育官方网站股份应邀参会,并作产品展示。本次...

-

07

2025-01

凝心聚力共拼搏 健步奋进新征程 ---伟德体育官方网站股份开展...

为深入学习党的二十届三中全会精神,贯彻落实习近平总书记关于工人阶级和工会工作的重要论述,丰富广大职工文化活动,增强职工队伍的凝...

-

25

2024-09

公司组织开展党支部委员党建业务知识培训

为进一步提升组织委员业务能力,9月4日下午,公司党委工作处对各支部组织委员进行了业务知识专题培训。党委工作处负责人结合历年西电集...

-

09

2024-07

党建联建聚合力 校企同行谱新篇 ---伟德体育官方网站股份所属...

为深入开展学习贯彻习近平新时代中国特色社会主义思想主题教育,热烈庆祝中国共产党成立103周年,7月2日,综合管理第一党支部与宝鸡文理...

-

31

2023-07

传承红色基因 激发团队斗志---零件产品制造部党支...

为进一步传承红色基因,激发团队斗志,激励党员群众全力冲刺下半年生产任务,近日,零件产品制造部党支部组织前往汉中留坝县江口镇红二...

-

10

2025-07

中国西电集团又一项目成功实现全容量并网

近日,西电新能源总包建设的河北东光县200MW风电项目最后一台风机成功完成调试项目正式实现全容量并网发电。在叶片转动间,将自然之力转...

-

22

2025-04

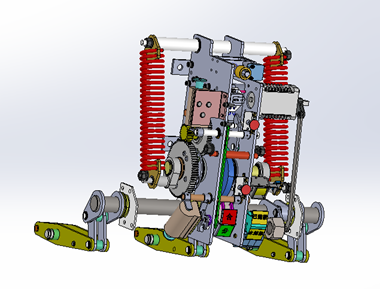

中国西电集团所属企业精彩亮相2025汉诺威工业博览...

近日,2025年汉诺威工业博览会在德国汉诺威盛大开幕。作为中国真空灭弧室行业的领军企业,中国西电集团所属伟德体育官方网站集团携多款创新产品精彩...

-

22

2025-04

“一带一路”朋友圈再扩大!

近日,天津港碧波荡漾,随着一声悠长汽笛,载有中国西电集团所属西电光电缆接触线、承力索产品的货轮劈波斩浪驶向马来西亚。这批凝聚中...

-

22

2025-04

中国西电集团党委书记、董事长、总经理韩兵会见华...

近日,中国西电集团党委书记、董事长、总经理韩兵在公司本部会见了来访的华为数字能源中国区副总裁雷光友,双方就加深新能源领域合作开...

0917-3561172

0917-3561172

陕西省宝鸡市伟德体育官方网站路53号

陕西省宝鸡市伟德体育官方网站路53号